CTC Equipment and Materials

- HVLP system with 1.3mm nozzle and PSI of 20 - 25

- Disposable cup system

- Masking tape

- Filter - 120 mesh or 125 micron

- Properly prepared and masked substrate

- Heat gun - Essential in the Conductive Top Coat process because it provides both heat and airflow needed for proper curing of the film.

CTC Application Key Points

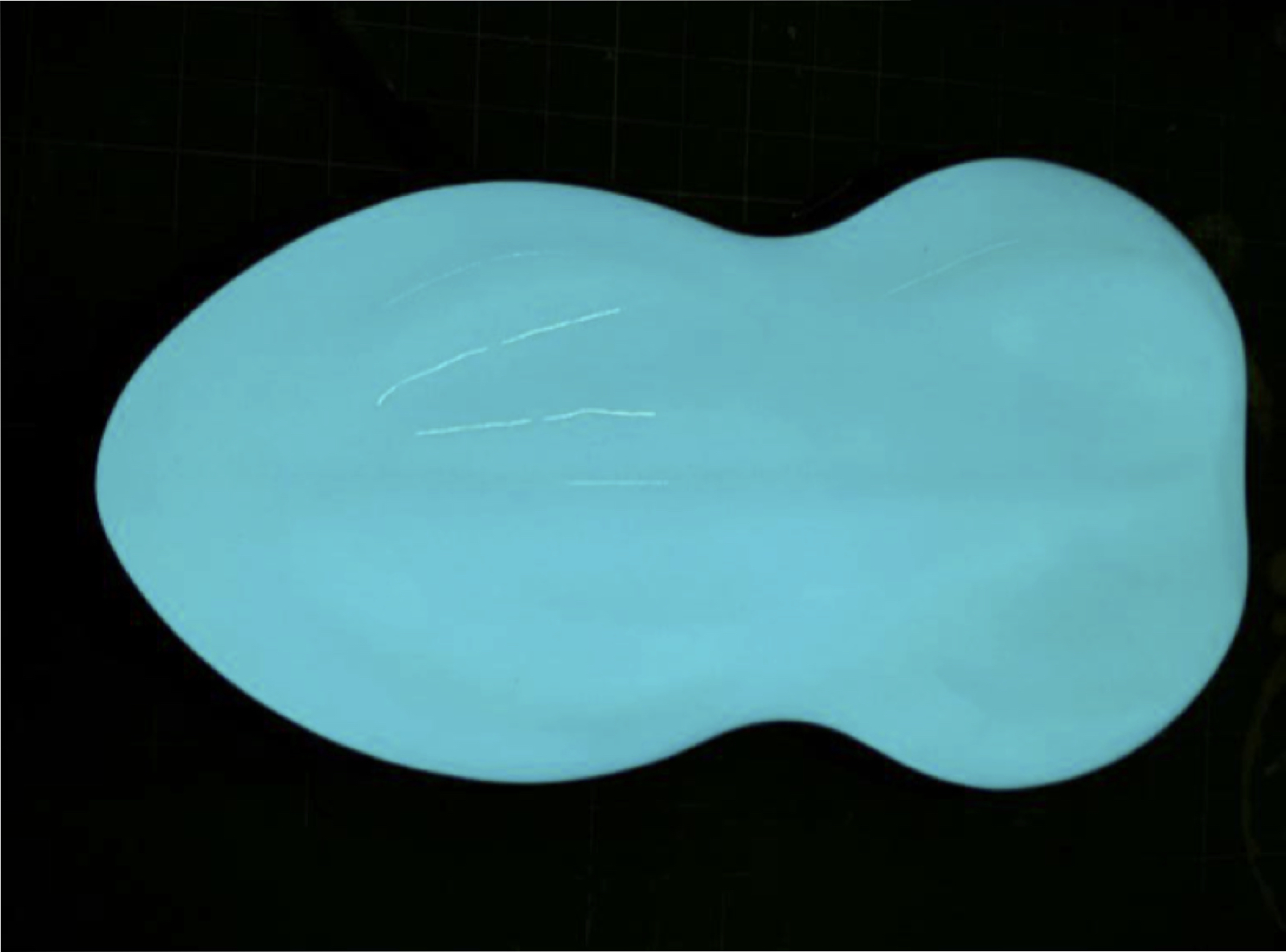

Water based, sprayable, translucent, conductive paint with a slight blue tint.

Conductive Top Coat is pre-mixed and ready to spray.

Conductive Top Coat is to be sprayed with the fluid needle completely closed and with 4 half turns out.

The Conductive Top Coat will have an almost translucent navy blue color before being applied. If it has a coagulated to solid appearance, it is unusable and should be discarded.

Conductive Top Coat must be applied in an even and consistent manner.

DO NOT allow Conductive Top Coat to freeze.

Conductive Top Coat thickness is approximately .1 mil or 5-10 microns.

CTC Masking

Always make certain the substrate area around the desired LumiLor area is masked off at this step as the CTC is a conductive material and will carry power whenever applied beyond the desired LumiLor area.

Tape off connection sites.

Conductive Cop Coat only needs to be applied over the LumiLor materials (illuminated area and busbar). Mask off areas outside of the busbar so no CTC is applied on bare substrate

CTC Application

Step 1 - Agitate and Strain

- Agitate for 1 to 2 minutes

- CTC will foam if shaken vigorously; allow foam to settle before proceeding.

- Strain with 120 mesh or 125 micron filter

Step 2 - Apply First Coat

- Attach the inverter

- Confirm inverter is in the off position

- Attach to the connectors that are now attached to the substrate.

- Note: The large inverters are always attached to the substrate connectors before they are attached to the power supply, and are be unplugged in the opposite order; unplug inverter from power supply first then unplug the inverter from the substrate connectors.

- Turn the inverter to the on position

- Spray a medium wet coat of Conductive Top Coat over the entire substrate where LumiLor has been previously applied with a 50% to 75% overlap.

- Immediately after the Conductive Top Coat has been applied, turn off the normal house lights and began to dehydrate the Conductive Top Coat with a heat gun.

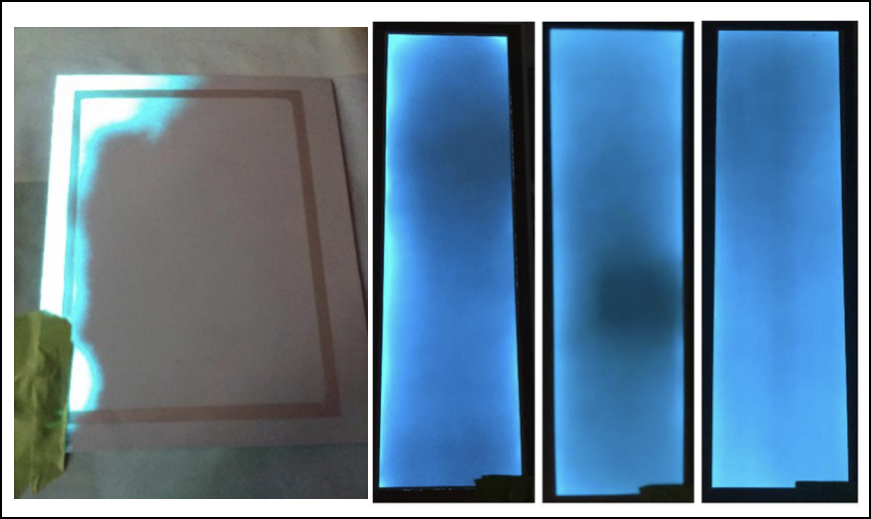

- Initially you will notice a thin illuminated area closest to the busbar.

- Once the Conductive Top Coat starts to fully dry the entire area where the backplane is located will start to illuminate.

- NOTE: The LumiLor light may fade away during the dehydrating process before it fully lights, keep dehydrating the CTC with a heat gun until the light comes back and fully illuminates.

- If, after the LumiLor fades away and comes back after dehydrating, the LumiLor still does NOT fully light then apply a second medium wet coat over desired surface and dehydrate with a heat gun.

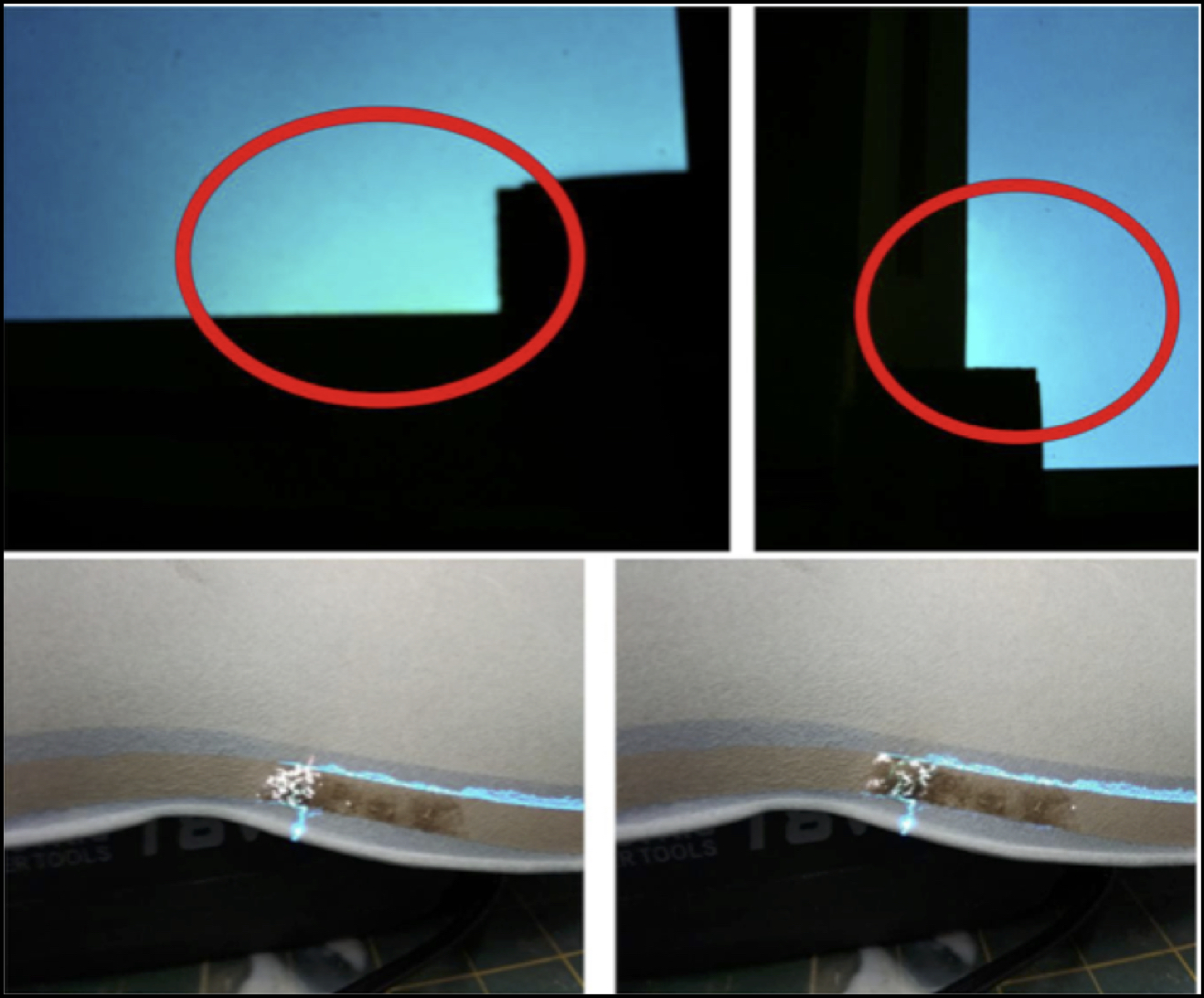

- After the entire area is illuminated, turn the normal house lights back on and inspect around the connection site that there is no burning or discoloration.

- If no burning or discoloration is taking place, then turn the inverter off and the illumination process is complete. Remove masking tape from connection site.

CTC Dry Time, Unused Material, and Clean-up

After applying CTC keep LumiLor under power (keep it lit) for 30 - 60 minutes and inspect for dim spots which may occur as the CTC dries. If dim spots appear apply more CTC to those areas, wait another 30 - 60 minutes, and inspect again.

Wait a minimum of 1 hour and no more than 24 hours before application of encapsulating clear.

Return unused material to original container after agitated in the spray gun cup.

Clean up (water based) - Clean any used containers and/or spray guns with water and rinse with acetone.

Dry times will vary based on local environmental conditions.

Why is there a humming noise when LumiLor is powered on?

The humming is caused by the specific inverter being used. LumiLor samples and Starter Kits include a cost effective inverter which may have an audible hum.

The humming is eliminated in more advanced inverters.

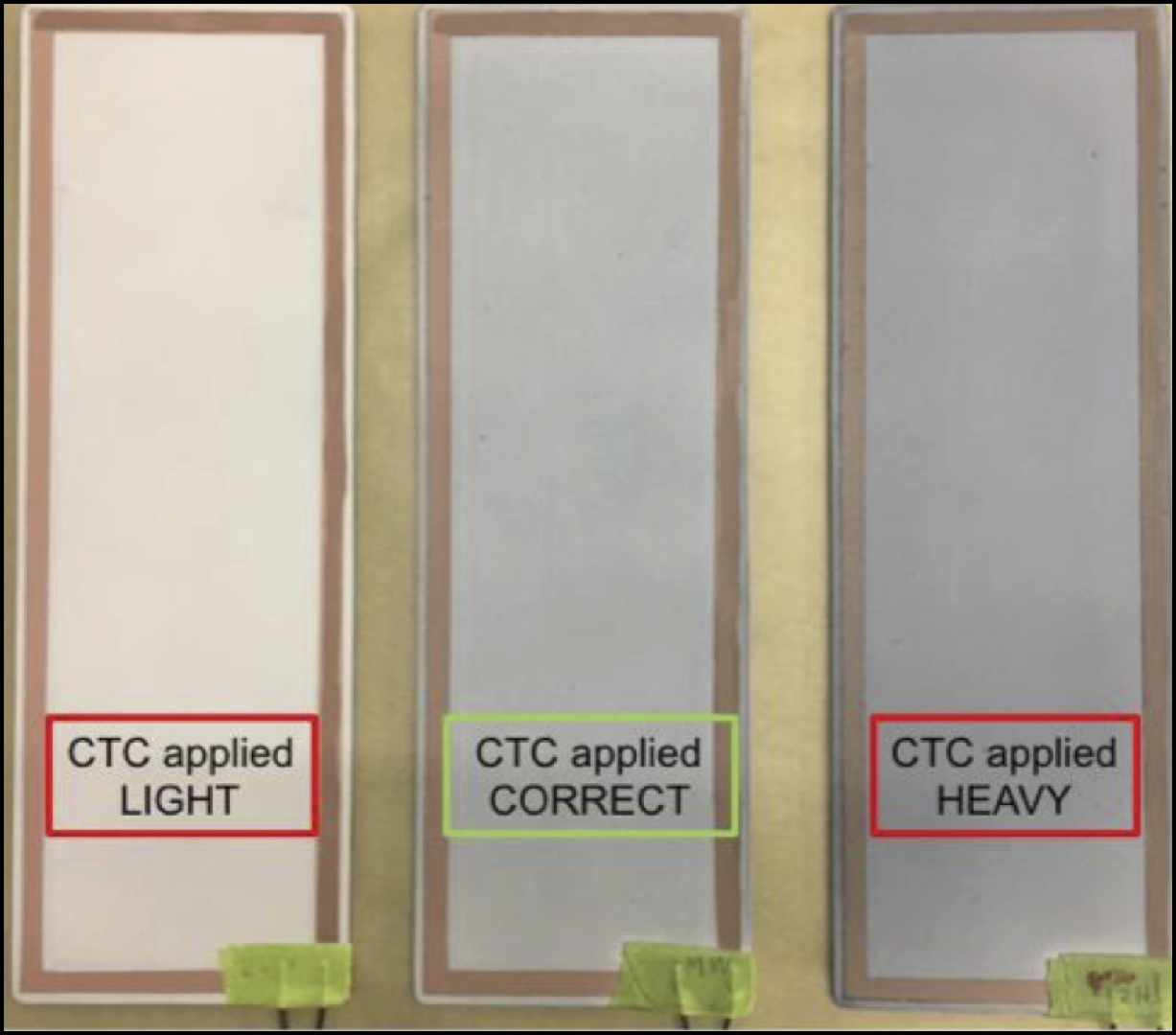

Conductive Top Coat Visual Reference Guide

Properly applied CTC produces a smooth and even finish.

Conductive Top Coat - Partial non-illumination of LumiLor after completely dry

- Power - On

- Cause - Conductive Top Coat applied too thin

- To Correct This - Apply more CTC evenly to entire surface in light coats until the entire surface lights consistently

-

To Avoid This - Apply one full medium wet coat within 12 hours

Conductive Top Coat - Burning around edges. Will generate heat.

- Power - On

- Cause - Insufficient insulation; dielectric applied too thin.

- To Correct This - Not fixable; need to remove LumiLor and restart.

-

To Avoid This - Apply proper thickness of dielectric according to instructions.

Conductive Top Coat - Light / Dark appearance with power off

- Cause - Conductive Top Coat applied too light or too heavy

- To Correct This - More CTC can always be applied; CTC can never be removed

-

To Avoid This - Apply Conductive Top Coat to according to guidelines