What is LumiLor?

LumiLor is a patented Light Emitting Coating (LEC) system which allows anything coated with it to illuminate. LumiLor works with electroluminescence (EL), an optical and electrical phenomenon in which a material emits light in response to an electric current.

Video: How LumiLor Works

LumiLor Terminology

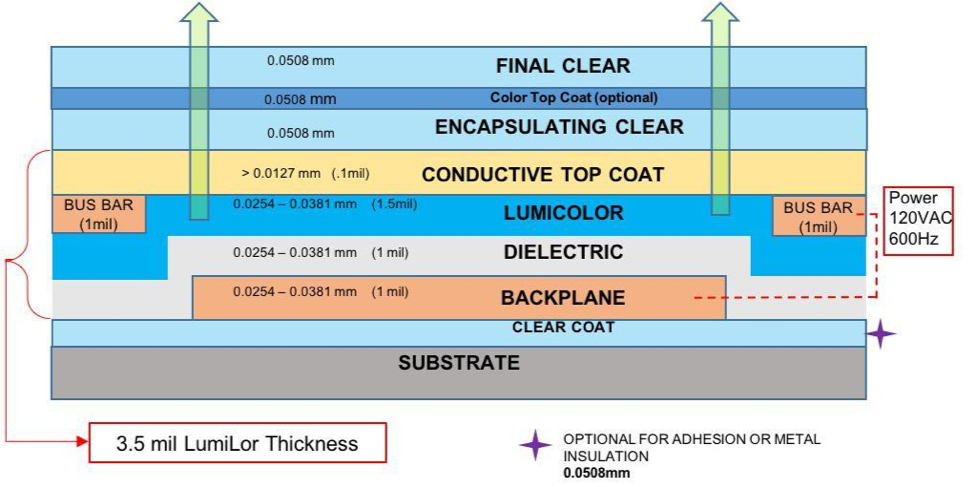

LumiLor is a multi-layer, sprayable, electroluminescent coating system consisting of backplane, dielectric, LumiColor, busbar, and Conductive Top Coat collectively known as the LumiLor Stack.

Backplane - Highly conductive and low resistance it supports the electrical current across the entire illuminated surface.

Backplane - Highly conductive and low resistance it supports the electrical current across the entire illuminated surface.

Dielectric - Applied over the backplane and under the busbar to insulate them and insure there is no burning or shorting.

LumiColor - Large particle material which emits light when under power.

Busbar - Backplane material used to create a low resistance path for better distribution of electrical current.

Conductive Top Coat - Translucent conductive material which allows the electrical current to be distributed to produce light.

Encapsulating Clear or Encapsulating Top Coat- Automotive grade speed clear coat to protect from elements, contamination, and ultra-violet rays. It also encapsulates the electrical current to protect from electrical shock and provides a surface for optional top coating.

Properties of LumiLor

- LumiLor is thin, it has a thickness of approximately 4.6 mils when applied according to specifications

- Cool to the touch even when emitting light

- Flexible up to nearly 180 degrees

- Reliable with no filament to break

- Highly visible at great distances and in darkness, smoke, fog etc.

- Easy to look at, pleasing to the eye

- Low energy consumption

What Color is LumiLor When Lit and Unlit?

LumiLor is available in eight colors, these are colors you see when LumiLor is lit.

- Green

- Aqua

- Blue

- White

- Yellow

- Pink

- Violet

- Orange

Unlit LumiLor appears as a gray hue, similar to an automotive primer.

Top Coats, Opacity, Transparency, and Light

Anything placed over LumiLor will absorb a certain amount of light.

Opaque top coats are used to hide the light you want to block.

Transparent paints, such as pearls and candies, can be used to tint the color.

The heavier a transparent top coat is applied the more light it will block.

Experiment with how your top coat appears with LumiLor in both the 'on' and 'off' states.

Artwork can be applied over LumiLor including airbrushing, hydrodipping, spray chrome, etc.

Red tones can be achieved by top coating LumiLor with tinted clear coats or colored top coats such as candies and pearls, or even with hydrographics. This is typically applied over white LumiLor to provide the most true color effect.

Always test top coats on a sample to see how they will look.

What Can LumiLor Be Applied To?

LumiLor can be applied to any non-porous substrate including but not limited to

- Plastic, vinyl, metal, wood, fiberglass, carbon fiber

Adhesion promoters can be used with some substrates but must have automotive clear applied over it before the LumiLor application.

- Glass, rubber, HDPE plastics

See Substrate/Material Testing and Preparation for more details.

How Long Will LumiLor Last?

LumiLor can last 10,000 power-on hours or more when properly applied and powered.

What is the Shelf Life and How Should LumiLor be Stored?

- Shelf life is 6 months from date on the bottle or can

- Ideal storage is in ambient temperatures between 70℉ and 75℉

- Do not allow LumiLor to freeze

- Do not store bottles and cans upside down

- Do not store in direct sunlight or under ultraviolet light

Basic Electronics Knowledge

For more information see Basic Electronics Terminology

ASTM Testing (American Society for Testing and Materials)

LumiLor has been proven to pass

- ASTM D3359 - Crosshatch and X Adhesion

- ASTM 1308 Chemical Testing - Varied

- ASTM D2794-10 - Impact Resistance Front to 136 pounds, Back to 16 pounds

- ASTM D4587 - QUV-A to over 500 hours

- Custom Climate Cycling - room temperature to 40℃/100% Humidity to -10℃

What About Dents, Dings, or Scratches?

It depends on where the damage occurs. If the power path is damaged the power would be cut off and LumiLor will not illuminate. It is possible to fix damage like this.

If the damage is inside the lit area you will see a dark spot where the damage took place. This type of damage cannot be repaired and should be encapsulated with clear coat to protect it.

What are the Safe Operating Temperatures of LumiLor?

LumiLor operates safely between -40℉ and 180℉ or -40℃ to 82℃

How Flexible is LumiLor?

LumiLor can be rolled back 180 degrees. Folding will cause cracking in the materials.

How will LumiLor React to Car Waxing and Buffing?

There is no direct impact because LumiLor is covered with an automotive grade clear coat, so any waxes, polishes, etc. will be on the clear coat and not directly on LumiLor.

Is LumiLor RoHS Compliant?

Yes. All layers of LumiLor have passed RoHS testing.

Tests |

Results/Unit |

Method |

|---|---|---|

Br, Cd, Cr, Hg, Pb |

Passed |

XRF Screening |

Electroluminescence - History and Explanation

Electroluminescence (EL) is an electrical and optical phenomenon that was first observed in 1907 by Captain Henry Joseph Round, however, the first published science paper was not written until 1936 by George Destriau. The next 75 years saw great improvements in the technology in terms of lifetime and brightness until it became a suitable light source for many applications.

In 2009, Andy Zsinko invented the first sprayable EL technology, LumiLor.

Electroluminescence works by the stimulation of phosphor crystals in an electromagnetic field.

The flow of alternating current from the negative to the positive terminal is interrupted by the insulating properties of the phosphor and dielectric layers.

Because the flow of the current is interrupted, the negatively charged electrons builds up a negative charge on one of the electrodes which in turn builds up a positive charge on the other electrode. This build-up of electrical charge creates a powerful electrostatic field between the two electrodes.

This electrostatic field acts upon the atoms in the phosphor crystals to stimulate light emission through the electroluminescent effect.

LumiLor Research and Development?

Over $4,000,000 has been invested in testing and certifying LumiLor to assure that, when properly applied, your paint job remains bright, and does not crack, peel, or delaminate.

LumiLor is subjected to the harshest standards an automotive base coat is asked to endure. We have demonstrated the ability to pass ASTM G154, where UV light and water vapor rapidly weathers a panel. We have run this test for over 400 hours without incurring a loss in brightness, adhesion, or film quality.

We have also demonstrated LumiLor can pass ASTM D3359, where we test the adhesion of the film when the film is damaged through both an X test and a crosshatch. We actually go beyond the test method, and soak the panels in water for 24+ hours prior to applying the tape and testing the adhesion. In all circumstances, a properly applied LumiLor system can pass these enhanced tests without issue.

Note that we cannot certify LumiLor to these standards independently. Substrate, application, and top coat as a system must be tested in order to certify the coating for an application.